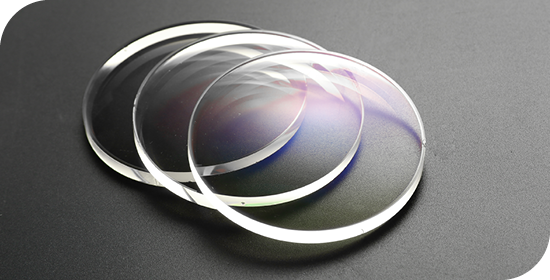

Hot-selling Abc Ophthalmic Lenses – CR39/NK-55/PC/MR Cyrstal Clear Lens – Hopesun Detail:

Clear lenses are the most commonly used for the corrective spectacles. Offering high-quality clarity, reducing light reflection, improving contrast and enhancing visual performance, their job is to provide crystal clear vision comfortably. Clear lenses are ideal for those who wear glasses all-day everyday. They are also good for those who like the look that wearing glasses gives them, even if their eyesight is great. In a word, clear lenses are great for everyone

Hopesun offers one of the finest selections of clear lenses in all the materials from 1.50 index up to 1.74 index. All lenses are made of the best quality materials in the world, such as CR-39 from PPG,MR series from Mitsui Chemicals to ensure lens clarity, safety, durability. Hopesun stock a huge range and amount of finished clear lenses in single vision, bifocal and progressive.

If you value quality, performance and innovation you’ve come to the right place.

Index&Material Available

Material Material |

CR-39 | NK-55 | Polycarbonate | MR-8 | MR-7 | MR-174 |

Refractive Index Refractive Index |

1.50 | 1.56 | 1.59 | 1.60 | 1.67 | 1.74 |

Abbe Value Abbe Value |

58 | 35 | 32 | 42 | 32 | 33 |

Specific Gravity Specific Gravity |

1.32g/cm3 | 1.28g/cm3 | 1.20g/cm3 | 1.30g/cm3 | 1.36g/cm3 | 1.46g/cm3 |

UV Block UV Block |

350nm | 385nm | 380nm | 395nm | 395nm | 395nm |

Design Design |

SPH | SPH | SPH | SPH/ASP | ASP | ASP |

CR39(1.50 refractive index): CR39 is characterized by high Abbe number, high transparency, strong wear resistance (without coating), low density (about half less than glass lens), good dyeing performance, solvent resistance, chemical resistance and heat resistance. And because the production process is mature, low cost, until now is still one of the mainstream materials in the lens industry. However, CR39 is less brittle than other materials in terms of impact resistance and tensile strength, so it is not suitable for rimless glasses (lenses tend to break when drilled), and it also has the lowest refractive index, making lenses thicker at higher degrees.

1.56 Refractive index: The raw material is usually NK55, which is often referred to as acrylic. The price is low and the utilization rate is high, but the light sense is weak. The lens is brittle, and it is easy to break when drilling the frame.

1.59 PC material: PC material is Polycarbonate, which is a thermoplastic plastic with refractive index of 1.59 and strong impact resistance. It can be used as bulletproof glasses and helmets in military field. It can be used in glasses without worrying about the breakage of lenses. It is suitable for rimless glasses. And the refractive index is higher than CR39, the lens can be made thinner. But as a thermoplastic material, its processing performance and chemical resistance is not good, not coated surface is also easy to scratch, wear resistance. In addition, its Abbe number is 30, which is 28 different from CR39.

MR material (1.60MR-8, 1.67MR-7, 1.74MR-174): MR™ is a series of medium and high refractive index resin materials developed by Mitsui Chemical Company in Japan. Except MR174, the whole series is made of polyurethane material (MR174 is a ring sulfur material with better dispersion resistance). Although the impact resistance is not as good as PC and Trivex, it has obvious advantages over CR39. In addition, the abbe number of this series of materials is moderate, heat resistance, weather resistance and chemical resistance is good, so it has a good comprehensive performance.

Explore Our Clear lenses

Single Vision

● SV 1.50

● SV 1.56

● SV 1.74

● SV 1.59PC

● SV 1.60

● SV 1.67

Bifocal

Progressive

● PRG 1.50

● PRG 1.59PC

● PRG 1.56

Product detail pictures:

Related Product Guide:

Our mission will be to grow to be an innovative supplier of high-tech digital and communication devices by giving worth added design and style, world-class production, and service capabilities for Hot-selling Abc Ophthalmic Lenses – CR39/NK-55/PC/MR Cyrstal Clear Lens – Hopesun , The product will supply to all over the world, such as: Nigeria, Ecuador, Chile, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in public placesand other industries. Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.